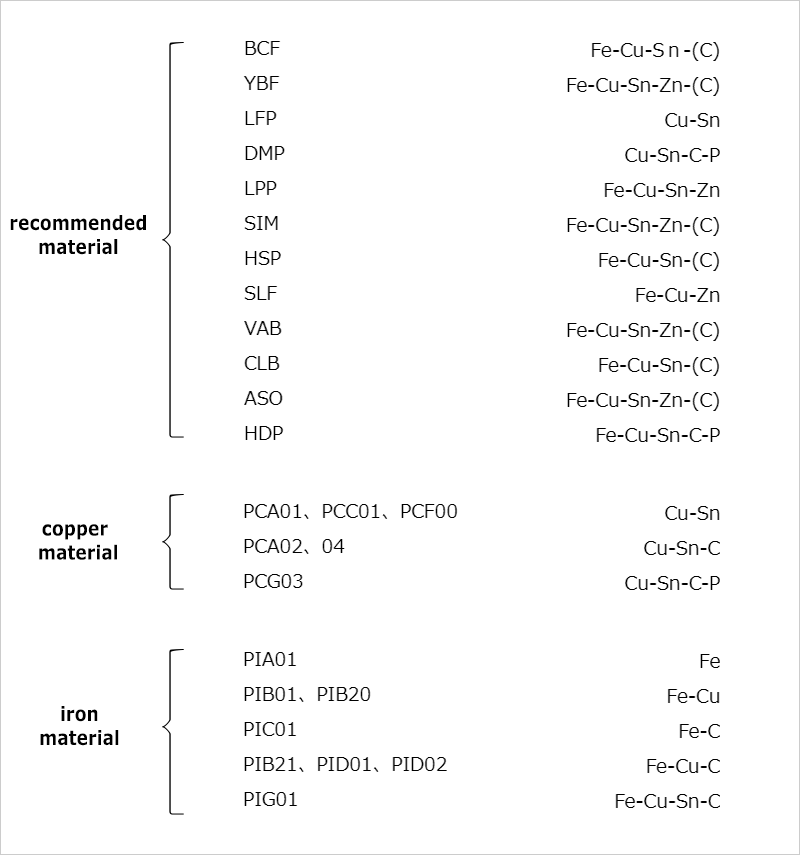

Materials Sintered Oil-impregnated Bearings

Sintered Oil-impregnated Bearings Typical Material Characteristics

| material mark | chemical ingredients | density (x103kg/m3) |

oil content (vol%) |

radial crushing strength (MPa) |

allowable PV value MPa・ m/min |

features/examples of usage /other | standard concerned(reference) ISO5755:2012 JISZ2550:2016 |

|

|---|---|---|---|---|---|---|---|---|

| Recommened material | BCF | Fe-Cu-Sn-(C) | 5.8〜6.6 | 18min | 200min | 150 | good unti-wear , good sliding characteristic equivalent to copper material | ―― |

| YBF | Fe-Cu-Sn-Zn-(C) | 5.8〜6.6 | 18min | 160min | 125 | good unti-rust , low friction, suits for micro bearing | ―― | |

| VAB | Fe-Cu-Sn-Zn-(C) | 5.3〜6.1 | 23min | 160min | 125 | ODD spindle motor (CD, DVD, Blueray), LBP polygon sccaner, DLP color wheel motor | ―― | |

| ASO | Fe-Cu-Sn-Zn-(C) | 5.7〜6.5 | 18min | 200min | 150 | Fe-Cu material for general purpose (home appliance ,aoutomotive ,office qquipment etc) | ―― | |

| LPP | Fe-Cu-Sn-Zn | 5.8〜6.6 | 18min | 160min | 125 | Fan motor | ―― | |

| CLB | Fe-Cu-Sn-(C) | 5.5〜6.3 | 24min | 150min | 125 | High oil content ,Fan motor, Haptices device | ―― | |

| LFP | Cu-Sn | 6.8〜7.8 | 12min | 100min | 60 | Low friction , Fan motor | ―― | |

| SLF | Fe-Cu-Zn | 6.7〜7.7 | 12min | 100min | 60 | Low friction (improved from LFP), Fan motor(quiet model) | ―― | |

| HSP | Fe-Cu-Sn-(C) | 6.0〜6.8 | 18min | 150min | 150 | Good for high speed rotaion | ―― | |

| SIM | Fe-Cu-Sn-Zn-(C) | 5.8〜6.8 | 18min | 150min | 150 | Suit for micro bearing , vibration motor, small stepping motor | ―― | |

| DMP | Cu-Sn-P-C | 7.0〜7.6 | 6min | 180min | 185 | Low spped , High load | ―― | |

| HDP | Fe-Cu-Sn-P-C | 5.9〜6.7 | 15min | 200min | 210 | suit for high load application , unti vibration, wiper, ETC, EGR ,etc | ―― | |

| Copper material | PCA01 | Cu-Sn | 6.4〜7.2 | 18min | 150min | 100 | Cpper material for general purpose (home appliance ,aoutomotive ,office equipment etc) | C-T10 |

| PCA02 | Cu-Sn-C | 6.2〜7.0 | 18min | 150min | 100 | Cpper material for general purpose | C-T10G | |

| PCA04 | Cu-Sn-C | 6.2〜7.0 | 12min | 50min | 100 | Wiper motor , Micro motor | C-T10G | |

| PCC01 | Cu-Sn | 6.4〜7.2 | 18min | 160min | 125 | Washer motor, Geared motor ,Starter motor | C-T10 | |

| PCF00 | Cu-Sn | 6.4〜7.2 | 18min | 150min | 125 | Micro motor, Acoustic equipment, Air conditioner | C-T10 | |

| PCG03 | Cu-Sn-P-C | 7.0〜7.6 | 6min | 180min | 185 | Low spped , High load (same as DMP) | ―― | |

| Iron material | PIA01 | Fe | 5.6〜6.4 | 18min | 170min | 60 | Wiper motor , Micro motor | F-00 |

| PIB01 | Fe-Cu | 5.6〜6.4 | 18min | 200min | 75 | Iron material for general purpose (home appliance ,aoutomotive ,office qquipment etc) | F-00C2 | |

| PIB20 | Fe-Cu | 5.6〜6.5 | 18min | 150min | 125 | Ventilating fan, Electric fan ,Blower fan motor | F-03C22 | |

| PIB21 | Fe-Cu-C | 5.6〜6.5 | 18min | 150min | 125 | Wiper motor , Micro motor | F-03C22G | |

| PIC01 | Fe-C | 5.6〜6.4 | 18min | 200min | 75 | Office equipment | ―― | |

| PID01 | Fe-Cu-C | 5.6〜6.4 | 18min | 280min | 125 | Office equipment , door hinge bush | ―― | |

| PID02 | Fe-Cu-C | 5.4〜6.4 | 18min | 200min | 125 | Geared motor , Washing machine | ―― | |

| PIG01 | Fe-Cu-Sn-C | 5.4〜6.4 | 18min | 200min | 125 | Washing machine, Laundry dryer, Dehydrator, Electric fan motor | ―― | |

*Please contact us as the bearing characteristics such as operating temperature range, wear resistance, and current loss will change depending on the impregnated oil.