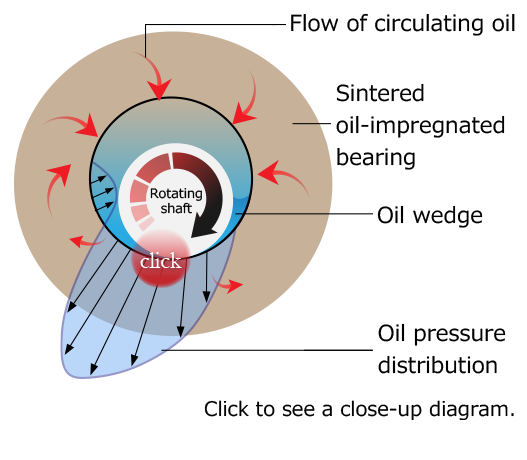

A sintered oil-impregnated bearing is a bearing that lubricates itself during use and is made using powder metallurgy technology whereby metal powder is packed and then heated to form a product which is then impregnated with oil via the many pores that are characteristic of sintered materials.

Strengths of Sintered Oil-impregnated Bearings

- Used in a wide variety of areas including automobiles, home appliances, and digital products.

- A range of advice can be provided on the basis of a bearing analysis after a reliability test for Porite products.

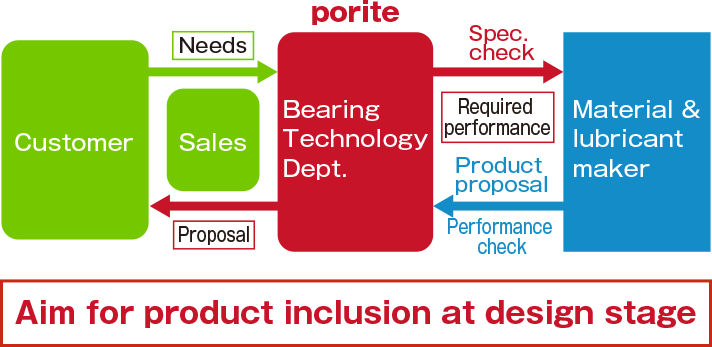

- Porite has in place an agile and adaptable system for customer-focused problem solving R&D and proposal-driven R&D.

- Porite is in a stronger position than its competitors thanks to its patented technology.

- Bearing performance evaluation tests are available with a testing device developed by Porite.

- Porite can undertake development of presses, automation devices, and other such things.

- We undertake joint development of specialized oil for sintered oil-impregnated bearings with major lubricating oil manufacturers.

- In-house design and production of precision molds is possible.

- We always aim to have our products incorporated in customers’ projects, so we are able to participate from the development phase.

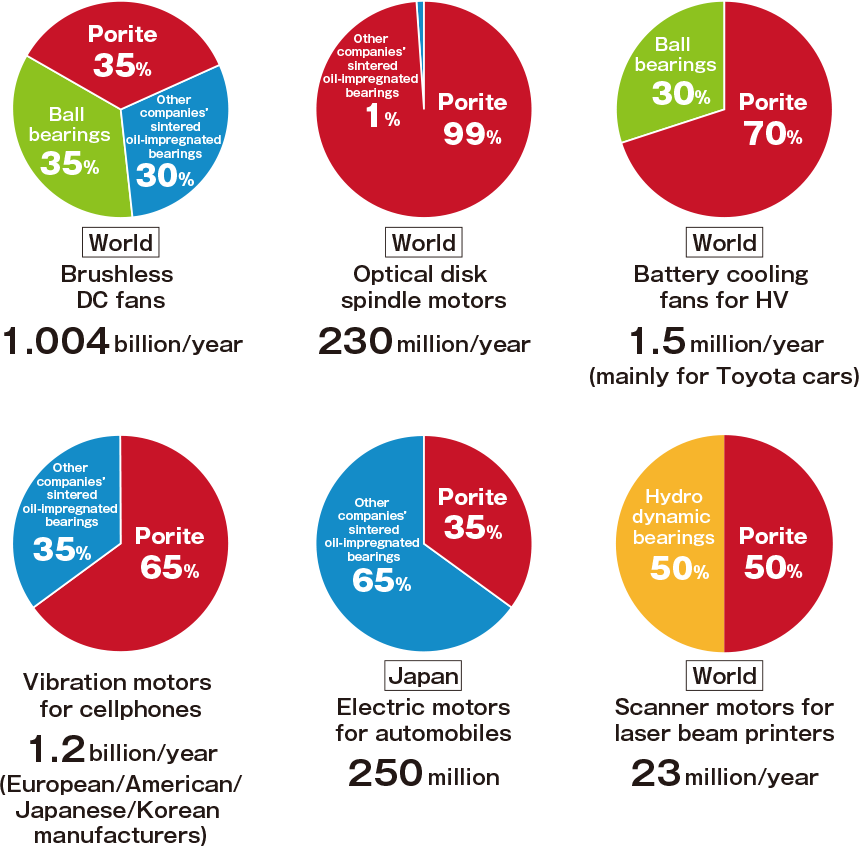

Sintered Oil-impregnated Bearing Production Record 8 Billion/Year

World No.1 Share for Sintered Oil-impregnatedBearings for Micro Motors

Bearing Technology Dept. Development/Evaluation Framework