Here you can find out about media coverage of Porite and the company’s award history.

As a global leader in powder metallurgy, Porite will continue to work to strengthen the Porite brand and promote it both in Japan and overseas.

FY2018

Japan Powder Metallurgy Association New Product Award / New Design Category

Sintered oil-impregnated bearings with an inner diameter tolerance of 1μm

Porite received this award for its ability to achieve an inner diameter tolerance of 1μm with standard sizing alone, and the fact that this kind of high precision can be achieved with costs 30% lower than conventional rotational sizing.

This has enabled usage in high precision motors that have exacting demands for characteristics in terms of noise, and it is anticipated that the powder metallurgy product market will expand henceforth as ball bearings and fluid dynamic bearings are replaced.

FY2018

Japan Powder Metallurgy Association New Product Award / New Design Category

Sintering of eccentric bushings for motorcycle ABS hydraulic control units

Porite received this award for the method it used to meet users’ demands, whereby copper-based bearing material is used for machine structural components that usually use iron-based bearing material.

Porite’s contribution to the industry was recognized in terms of its use of sintered components for eccentric bushings for motorcycle ABS hydraulic control units, demand for which is expected to expand greatly going forward.

FY2018

Japan Powder Metallurgy Association New Product Award / New Design Category

Sintering of lead screw nuts for medical-use syringe pumps

Porite received this award for achieving vastly reduced costs using the characteristics of sintered oil-impregnated bearings, and successfully replacing high-cost machine processed products.

Furthermore, products with similar characteristics are anticipated to be applied to actuators in things such as small robots for which growth henceforth is expected.

FY2016

Japan Powder Metallurgy Association New Product Award / New Design Category

Sintered oil-impregnated bearings for high-efficiency motors with dimples on inner diameter

Porite received this award for novelty and originality in terms of approaching the friction coefficient of conventional ball bearings by machining highly precise, regularly spaced dimples on the inner diameter of φ5mm or lower while also re-finishing to ensure this causes no impact on inner diameter precision.

Another reason for the award was the fact that the market can be expected to grow henceforth as the cost of this is half that of ball bearings.

2016

November 11

Received the Forging Industry Technology Award from the Sokeizai Center for the development of sintered oil-impregnated bearings with minute dimples on the inner diameter

2016

April 7

Received the Award for Excellence from The Resona Foundation For Small And Medium Enterprise Promotion for sintered oil-impregnated bearings with dimples on the inner diameter for high-efficiency motors

FY2015

Japan Powder Metallurgy Association Incentive Award

Development of bearings for linear oscillatory actuators for wearable and other devices.

Porite received this award for technology to put a miniscule R-shape on ultra-small bearings. Also, another aspect was the fact that these bearings enabled entry into a new field for sintered materials through their incorporation in wearable devices (a new usage) and a production record of three million per month.

FY2014

Japan Powder Metallurgy Association Incentive Award

High temperature resistant sintered oil-impregnated bearings for automobile valve open/close motors

Performance improvement through sintering material optimization and the development of new fluorine oil.

The award was received in recognition of the fact that the product’s scope of application extends as far as the field of ball bearings.

2014

November 7

Accredited as a “2014 Saitama City Leading Edge Company”

2014

November 7

Received the Forging Industry Technology Award and Incentive Award from the Sokeizai Center for the development of integral bearings for battery cooling fan motors

FY2013

Japan Powder Metallurgy Association New Product Award / New Design Category

Development of bearings for battery cooling fan motors used in HEV/EVs

Porite received this award for the ingenuity of its molding and assembly methods and for achieving a high degree of coaxiality precision of 1μm.

Another reason for the award was the switch from ball bearings to sintered oil-impregnated bearings in the field of HEV/EVs, for which sales growth can be expected henceforth.

FY2012

Japan Powder Metallurgy Association New Product Award / New Materials Category

Low-noise sintered oil-impregnated bearings for fan motors in ultra-slim notebook PCs

Porite received this award in recognition of the fact that it achieved both wear resistance and a snug fit (things that are normally in a trade-off relationship with each other) by using a metal structure design, cost reduction, the replacement of small dynamic pressure bearings with sintered oil-impregnated bearings, the adoption of sintered bearings in the notebook PC market, and mass production.

2011

November 11

Re-accredited as a “Saitama City Technical Brand Company”, which is given by Saitama City to leading R& companies in the city that exhibit excellent creativity and innovation in their technology.(First accreditation in 2008)

2011

March 29

Porite’s main office plant accredited as an “Eco-Up” place of business by the governor of Saitama Prefecture.

FY2011

Japan Powder Metallurgy Association New Product Award / New Design Category

Development of low-noise sintered gears superior to plastic gears

Porite received this award because we leveraged structure control, low density, and other characteristics of sintered materials in order to achieve low noise, on top of which we achieved lower noise than insert plastic gears through increased gear precision while reducing costs, in addition to which there are high expectations for applications in different fields in the future.

FY2011

Japan Powder Metallurgy Association New Product Award / New Design Category

Sintered oil-impregnated bearings for ultrahigh speed motors

Porite received this award in recognition of the fact that we were able to design sintered oil-impregnated bearings for application in ultrahigh speed motors with a speed of 48,000rpm, and for the fact that we achieved massive cost reductions with the market expected to grow as the scope of application for these bearings expands.

FY2011

Japan Powder Metallurgy Association Incentive Award

High temperature resistant sintered oil-impregnated bearings for microwave ovens

Porite received this award for the development of sintered oil-impregnated bearings with an optimum airflow level and a shape to prevent oil leakage in order to use oil to ensure resistance to high temperatures, and for developing a new market when these bearings were incorporated into home appliances such as microwave ovens.

FY2010

Japan Powder Metallurgy Association New Product Award / New Materials Category

Anti-wear sintered oil-impregnated bearings with long lifespan for high loads

Porite received this award for vastly increasing lifespan for low-speed, high-load uses, and for achieving mass production of 600,000 units per month.

FY2009

Japan Powder Metallurgy Association New Product Award / New Materials Category

Sintered Oil-impregnated bearings for low-cost long-lifespan fan motors

Porite received this award for massively increasing the lifespan of sintered oil-impregnated bearings, and for its record of vastly increasing their potential to be used as an alternative to ball bearings.

FY2009

Japan Powder Metallurgy Association New Product Award / New Design Category

Development of components for 4WD switching device actuators

Porite received this award for successfully switching from conventional forged components to sintered ones and contributing greatly to user system performance improvement through improved precision, lighter weight, and significant cost reduction.

FY2009

Japan Powder Metallurgy Association Incentive Award

Development of steering tilt components with incomplete gear shape

Porite received this award for creating its own high-functionality design for components with an incomplete gear (for which quality assessment is very challenging) using the characteristics of powder metallurgy, and then achieved mass production.

FY2008

Japan Powder Metallurgy Association New Product Award / New Design Category

Stop rings with a flange at the top and bottom for FAN motors

Porite received this award for its technological (press fitting) ability to combine two small, thin-walled components with conventional methods instead of MIM, the fact that we brought to fruition an idea for incorporation into retaining mechanisms, and achieving mass production of 300,000 units per month.

2007

April 11

Chosen by the Minister of Economy, Trade and Industry’s Small and Medium Enterprise Agency as one of 300 vibrant manufacturing companies to support the Japan of tomorrow.

>Details(PDF:260KB)

FY2007

Japan Powder Metallurgy Association New Product Award / New Design Category

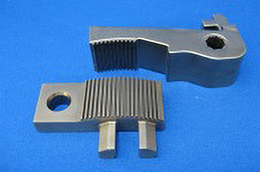

Development of overload clutch components for hammer drills

Porite received this award for participating from the development phase of a complex shape product and changing the material and shape to make it suitable to be manufactured with press-forming and sintering, thus providing an alternative to MIM and greatly reducing costs.

FY2007

Japan Powder Metallurgy Association New Product Award / New Design Category

Development of thin-walled long helical gears with irregularly shaped inner diameters

Porite received this award for its high-precision mass production of a product with thin-walled, long, involute serrations on the inner diameter and an outer diameter with a complex helical gear shape.

FY2007

Japan Powder Metallurgy Association Incentive Award

Low-cost sintered oil-impregnated bearings for automobile motors with excellent low and high temperature characteristics

Porite received this award for successfully creating sintered oil-impregnated bearing material that can be used across a wide range of temperatures and providing an alternative to ball bearings in the field of automobile motors through material and impregnating oil development.

FY2006

Japan Powder Metallurgy Association New Product Award / New Design Category

Development of clutch components for power slide doors

Porite received this award for expanding usage to a new hybrid clutch mechanism for power slide doors by taking maximum advantage of the characteristics of powder metallurgy, which offers high-precision, diversity in materials for the mass production of complex shapes, and use of pores, and greatly contributing to reducing unit weight and size for users.

FY2006

Japan Powder Metallurgy Association Incentive Award

Development of sintered oil-impregnated bearings for ultrahigh-speed polygon scanner motors

Porite received this award for the realization of sintered oil-impregnated bearings that can be applied in fields with high revolution speeds of 40,000rpm, thus expanding the field of application for bearings through a combination of bearing design and lubricant development.

FY2005

Japan Powder Metallurgy Association New Product Award / New Design Category

High temperature, high speed, long lifespan bearings for DLP

Porite received this award for finding an alternative to fluid dynamic bearings and ball bearings in the field of bearings for DLP wheel motors through development including a new type of oil.

FY2005

Japan Powder Metallurgy Association New Product Award / New Design Category

One-piece housing ‘nakanige’ bearings

Porite received this award for achieving performance improvement and large cost reductions by leveraging the advantages of powder metallurgy to create products in one piece.

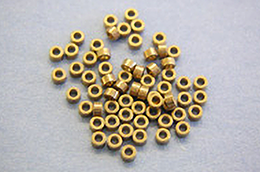

FY2004

Japan Powder Metallurgy Association New Product Award / Process Development Category

4mg sintered oil-impregnated bearings

Porite received this award for the development of elemental technology that enables the mass production of minute products including all stages from base material compacting to the subsequent secondary processing, thus expanding into an area of large demand in the form of cellphones.

FY2004

Japan Powder Metallurgy Association New Product Award / New Design Category

Bearings with lubricant self-recovery function

Porite received this award for achieving a lifespan to rival that of ball bearings, and for successfully expanding the scope of use into the field of cooling axial-flow fans for computers - an application that is expected to grow going forward.

FY2003

Japan Powder Metallurgy Association New Product Award / New Materials Category

Long-lifespan sintered oil-impregnated bearing material for R/RW, RAM, LBP spindle motors

Porite received this award for developing long-lifespan, highly reliable bearing material to meet the demands of increasingly fast devices and achieving the normally conflicting characteristics of increased oil impregnation ratio and strength improvement in this material.

FY2002

Japan Powder Metallurgy Association New Product Award / New Design Category

Bearing unit that prevents oil leakage with a sintered seal cap

Porite received this award for analysis of oil leak behavior leading to the conceptualization of a seal structure that utilizes the advantages of sintered material to achieve a longer bearing lifespan, and for developing a new field of use.

FY2002

Japan Powder Metallurgy Association New Product Award / New Materials Category

Lead-free and snug-fitting sintered material for VTR capstan bearings

Porite received this award for achieving performance that could once only be achieved with the inclusion of lead without the use of lead and for contributing to increased user productivity.